SOHC carburation and setting up

-

James Bowen

- Posts: 90

- Joined: June 23rd, 2006, 8:17 pm

- Location: Brighton, UK.

- Contact:

Andy,

Very many thanks. I see that they have 6 for part no. 72106, which they list as 42DCNF +40DCNF.

Part no. 72129 which is for 40DCNF only shows 2 available.

My Weber manual shows those part no.s correspond only for the 42DCNF and 40DCNF respectively. I'll give them a call tomorow, to see what'll fit.

And yes I was "james" on X1/9 owners site, but I think someone else has taken that moniker now, as I haven't been active on it recently.

How does your stroked 1600 unit run? Any idea on power and torque figures? And does any of the above running problems/difficulties relate to your own experiences at all?

Regards, james

Very many thanks. I see that they have 6 for part no. 72106, which they list as 42DCNF +40DCNF.

Part no. 72129 which is for 40DCNF only shows 2 available.

My Weber manual shows those part no.s correspond only for the 42DCNF and 40DCNF respectively. I'll give them a call tomorow, to see what'll fit.

And yes I was "james" on X1/9 owners site, but I think someone else has taken that moniker now, as I haven't been active on it recently.

How does your stroked 1600 unit run? Any idea on power and torque figures? And does any of the above running problems/difficulties relate to your own experiences at all?

Regards, james

-

lidox19

- Posts: 9

- Joined: June 22nd, 2006, 9:50 pm

- Location: Cheltenham, UK

- Contact:

Hi James,

I hope you had some success with the chokes.

I'm watching this thread with great interest as I have yet to set up the carbs on my 1603 motor.

I don't have any power or torque figures yet as the car is off the road at the moment awaiting some serious welding. If, no. When I get it back on the road I will be using the infomation from this thread as a starting point.

Your exhaust manifold is very interesting. Nice long primaries.

Unfortunately I'm using a CSC manifold (primaries way too short) with a home built 2" system. When it's all set up I will be happy with about 135 BHP and 115lbf ft. We'll see..

Good luck

Andy

I hope you had some success with the chokes.

I'm watching this thread with great interest as I have yet to set up the carbs on my 1603 motor.

I don't have any power or torque figures yet as the car is off the road at the moment awaiting some serious welding. If, no. When I get it back on the road I will be using the infomation from this thread as a starting point.

Your exhaust manifold is very interesting. Nice long primaries.

Unfortunately I'm using a CSC manifold (primaries way too short) with a home built 2" system. When it's all set up I will be happy with about 135 BHP and 115lbf ft. We'll see..

Good luck

Andy

1978 Lancia Beta Saloon 1600

1979 Fiat X1/9 Lido.1603cc 5 speed twin DCNF's

1979 Fiat X1/9 Lido.1603cc 5 speed twin DCNF's

-

James Bowen

- Posts: 90

- Joined: June 23rd, 2006, 8:17 pm

- Location: Brighton, UK.

- Contact:

-

James Bowen

- Posts: 90

- Joined: June 23rd, 2006, 8:17 pm

- Location: Brighton, UK.

- Contact:

Guy and all,

For info.....Camshaft timed in at the correct 106deg. I set it using the correct lift at TDC, then double checked that inlet was fully open at 106deg. It was previously set at 101deg Crank. So 5deg advanced. I didn't think it would be that far out.

Compressions tested as well... 202, 203, 202, 215.(measured in PSI) Number 4's exhaust valve clearance is a little off.. 0.35mm as opposed to 0.25mm, so I need to rectify that, but I assume that is why the slightly higher reading on number 4 exhaust valve being held closed for slightly longer?

The George Polley silencer arrived today. I need to get some sleeve's made up to fit the bigger inlet/outlet pipes onto the existing pipework, then try to reset the carbs. I presume the ignition will now be out, so really a rolling road session may be in order.

The George Polley silencer looks to be almost exactly the same as the current Jetex item, both internal (that I can see, but larger diameter perforated pipe) and external dimension. Will there really be a difference in back pressure?

Regards, James

For info.....Camshaft timed in at the correct 106deg. I set it using the correct lift at TDC, then double checked that inlet was fully open at 106deg. It was previously set at 101deg Crank. So 5deg advanced. I didn't think it would be that far out.

Compressions tested as well... 202, 203, 202, 215.(measured in PSI) Number 4's exhaust valve clearance is a little off.. 0.35mm as opposed to 0.25mm, so I need to rectify that, but I assume that is why the slightly higher reading on number 4 exhaust valve being held closed for slightly longer?

The George Polley silencer arrived today. I need to get some sleeve's made up to fit the bigger inlet/outlet pipes onto the existing pipework, then try to reset the carbs. I presume the ignition will now be out, so really a rolling road session may be in order.

The George Polley silencer looks to be almost exactly the same as the current Jetex item, both internal (that I can see, but larger diameter perforated pipe) and external dimension. Will there really be a difference in back pressure?

Regards, James

-

Guy Croft

- Site Admin

- Posts: 5039

- Joined: June 18th, 2006, 9:31 am

- Location: Bedford, UK

- Contact:

James

- I cannot say whether it will have the same but it will certainly not have more or too much. In fact it will have hardly any, I wouldn't use any other, think I already said that! Call it a low cost safety precaution. Point is - once fitted you can absolutely rule out silencer back-pressure as a potential cause of upset fuelling/calibration. Go back then to my previous notes carefully, OK?

GC

- I cannot say whether it will have the same but it will certainly not have more or too much. In fact it will have hardly any, I wouldn't use any other, think I already said that! Call it a low cost safety precaution. Point is - once fitted you can absolutely rule out silencer back-pressure as a potential cause of upset fuelling/calibration. Go back then to my previous notes carefully, OK?

GC

-

James Bowen

- Posts: 90

- Joined: June 23rd, 2006, 8:17 pm

- Location: Brighton, UK.

- Contact:

-

James Bowen

- Posts: 90

- Joined: June 23rd, 2006, 8:17 pm

- Location: Brighton, UK.

- Contact:

Hello,

Just a post script to say that Cam has now been retarded 5 degs. This seems to have pushed torque further up the rev range, and also made the delivery more uniform from low revs to mid range. I managed to steam easily into the rev limiter, currently set at 7,300 rpm because it wasn't worth going higher, so that'll be reset to 7,800rpm.

The George Polley silencer box fitted today, is a little louder but appears to have worked in the respect that the idle jets have been changed to 50's, and with re balancing the carbs, the car flys with lovely crisp acceleration through the progression stage, and a smooth idle.

I need to get my air correctors re drilled, as I think the top end is now too rich. Its a little sluggish. The 220's I had soldered up and re drilled to 130's could do with re drilling to 170's or 180 as Guy suggests. Does anyone know someone who still has some Weber drills?

All in all a good result thus far. Rolling road not planned for now, as I can't find any 34 chokes at the moment. But, point made earlier about knowing what you've got before moving on to the next stage. Many thanks Guy.

Regards James

Just a post script to say that Cam has now been retarded 5 degs. This seems to have pushed torque further up the rev range, and also made the delivery more uniform from low revs to mid range. I managed to steam easily into the rev limiter, currently set at 7,300 rpm because it wasn't worth going higher, so that'll be reset to 7,800rpm.

The George Polley silencer box fitted today, is a little louder but appears to have worked in the respect that the idle jets have been changed to 50's, and with re balancing the carbs, the car flys with lovely crisp acceleration through the progression stage, and a smooth idle.

I need to get my air correctors re drilled, as I think the top end is now too rich. Its a little sluggish. The 220's I had soldered up and re drilled to 130's could do with re drilling to 170's or 180 as Guy suggests. Does anyone know someone who still has some Weber drills?

All in all a good result thus far. Rolling road not planned for now, as I can't find any 34 chokes at the moment. But, point made earlier about knowing what you've got before moving on to the next stage. Many thanks Guy.

Regards James

- Attachments

-

- Pic of inside of the Jetex Silencer.

- P1180012.jpg (34.83 KiB) Viewed 10820 times

-

Guy Croft

- Site Admin

- Posts: 5039

- Joined: June 18th, 2006, 9:31 am

- Location: Bedford, UK

- Contact:

-

James Bowen

- Posts: 90

- Joined: June 23rd, 2006, 8:17 pm

- Location: Brighton, UK.

- Contact:

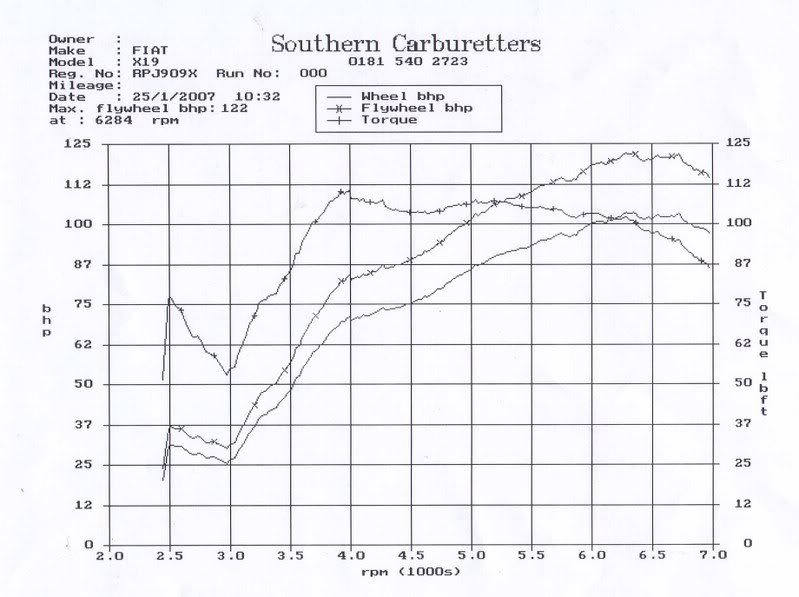

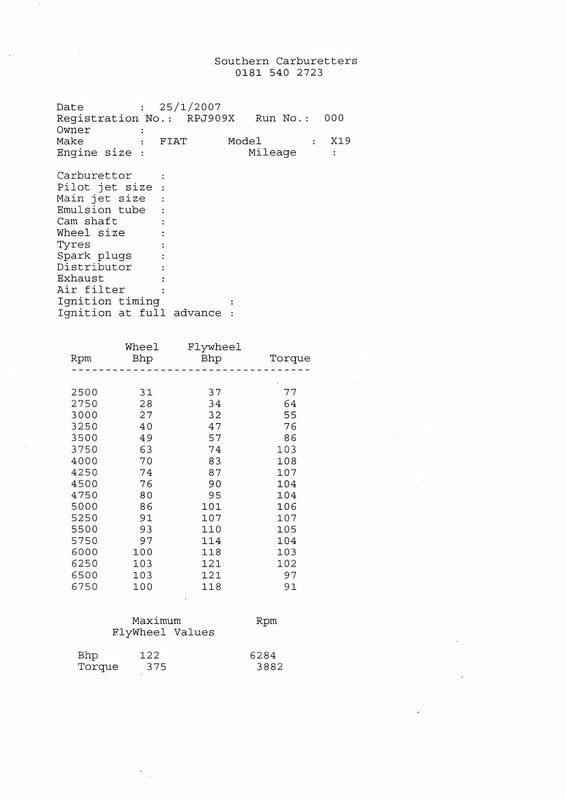

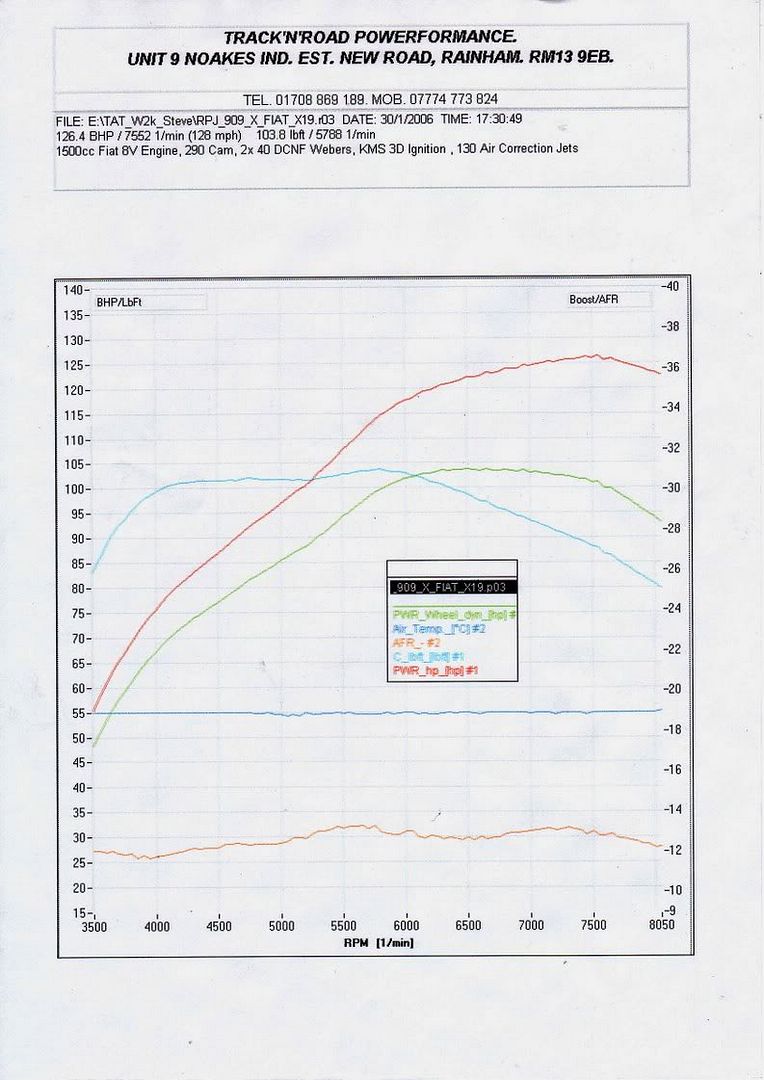

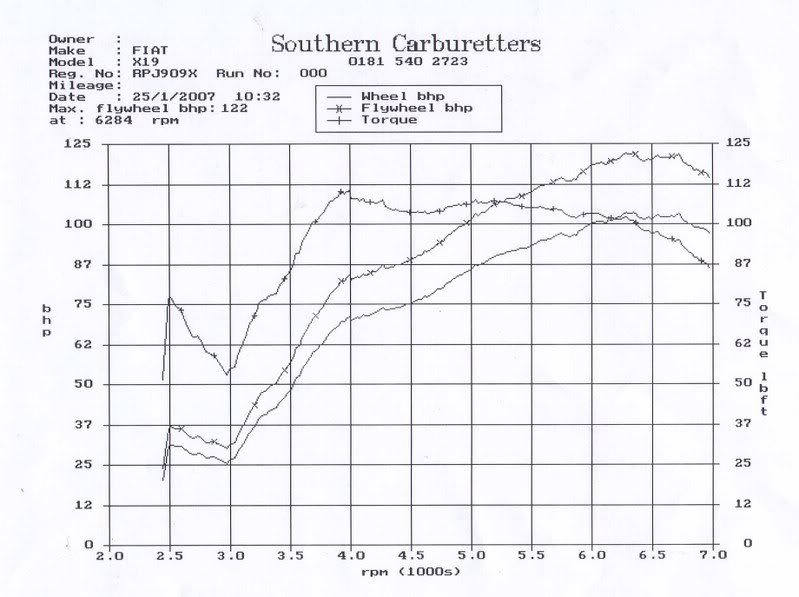

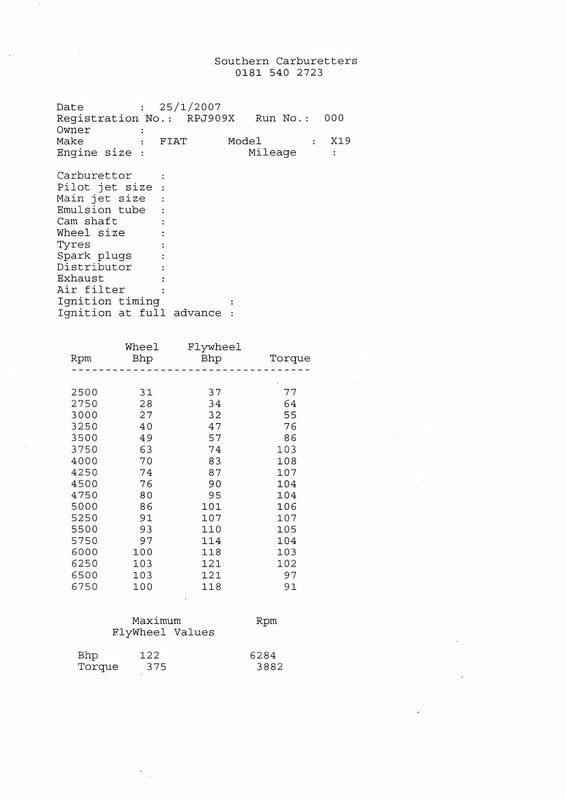

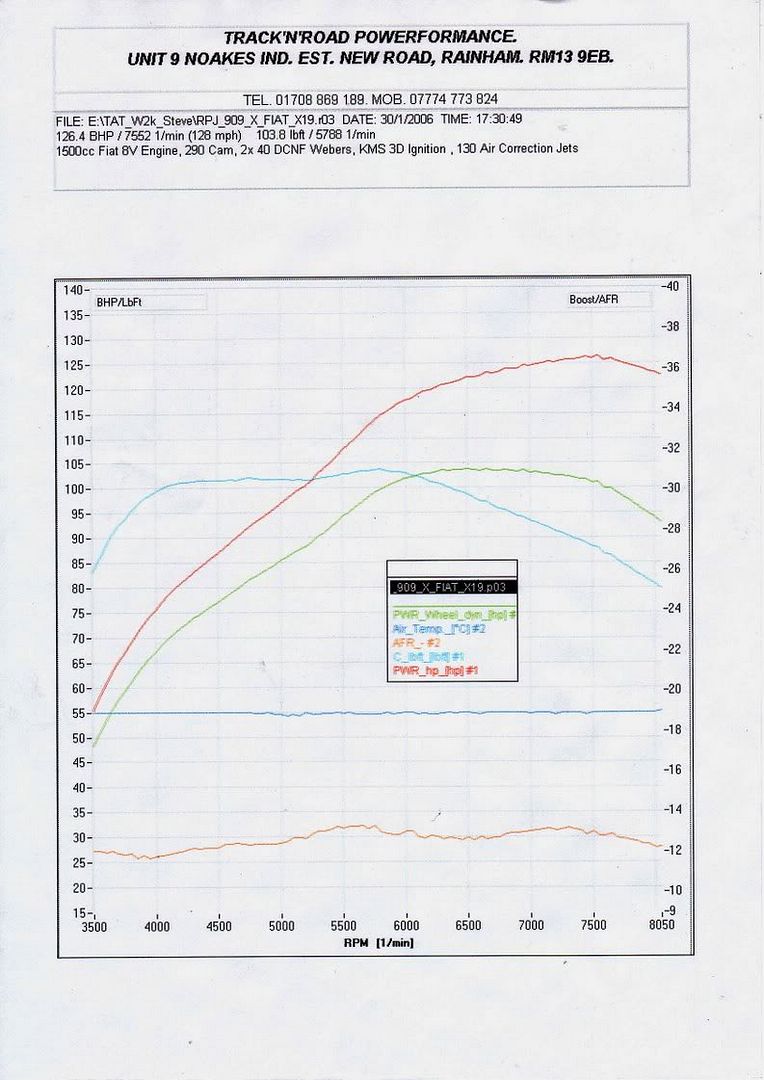

Disregard the last post by me.............I got the car onto a Rolling Road anyway. The below images are the results. Good in some ways, and a little vexing in others.

First off, the carb fuelling issue still seems to be the same. 130 air correctors are as big as I can go. They tried 120 Main Jets, and 115 Air correctors. This brought the bottom end fuelling up to a reasonable AFR, but no improvement in higher rpm use. They wanted to try F22 emulsion tubes but only had 2 in stock, so no go.

Torque appears to have risen from an average of 102 Lbft peak at 104 Lbft to an average of 105 LbFt peaking at 108 LBft. It comes up 200rpm LOWER than before, and starts to decend again 200 rpm LOWER down the rev range. I confess I was expecting the reverse, as I have retarded the cam 5 degs. from its previous postion. Power at the wheels remains unchanged, and Power recorded at the Flywheel is 4 BHP less. But I presume that Southern carbs and Trackformance have differing ways of working out Losses etc...

Fuel supply didn't appear to be an issue, with a sustained 6,000rpm load, there was no fuel decay.

Conclusions.....

1. Is it the length of Primary on the manifold causing problems?

2. Carbs not flowing enough air?

3. Cylinder head not flowing properly?

4. Other problem?

Comparrison with other Power plot.......

Regards James

First off, the carb fuelling issue still seems to be the same. 130 air correctors are as big as I can go. They tried 120 Main Jets, and 115 Air correctors. This brought the bottom end fuelling up to a reasonable AFR, but no improvement in higher rpm use. They wanted to try F22 emulsion tubes but only had 2 in stock, so no go.

Torque appears to have risen from an average of 102 Lbft peak at 104 Lbft to an average of 105 LbFt peaking at 108 LBft. It comes up 200rpm LOWER than before, and starts to decend again 200 rpm LOWER down the rev range. I confess I was expecting the reverse, as I have retarded the cam 5 degs. from its previous postion. Power at the wheels remains unchanged, and Power recorded at the Flywheel is 4 BHP less. But I presume that Southern carbs and Trackformance have differing ways of working out Losses etc...

Fuel supply didn't appear to be an issue, with a sustained 6,000rpm load, there was no fuel decay.

Conclusions.....

1. Is it the length of Primary on the manifold causing problems?

2. Carbs not flowing enough air?

3. Cylinder head not flowing properly?

4. Other problem?

Comparrison with other Power plot.......

Regards James

-

Guy Croft

- Site Admin

- Posts: 5039

- Joined: June 18th, 2006, 9:31 am

- Location: Bedford, UK

- Contact:

I'd suggested:

Choke 34mm

Main Jet 125

Air corrector 170-180

Idle - 45

Pump - 45 OK

And now you ran 120 mains - what choke size on F24 emulsion tube?

The cam retard (5 crank or cam degrees?) might enhance the lower end and cut the top end by reducing overlap. Hard to tell with a SOHC cam - I'd have left it alone at 106 like Cat specified - like I said - only change_one_thing_at_a_time, but now you have several new variables and a decent comparison of what worked and what didn't is er, pretty well impossible..

I wonder if it's time to go back to 106 deg. Or maybe change the header, it is too short really, I'd be specifying at least 4 " longer. I could be wrong, maybe your head flow is too low and she won't breathe higher up and maybe the cam profile is not working - but - I know one thing - over-rich jetting is nearly always a result of exhaust pressure wave interference from too-short header pipes. And tiny air correctors = way over-rich. They only influence the mixture at the top end - say 5000 plus and the fact they are so small (fuel-rich) means it is needing massive over-fuelling at the top end and struggling to get high rpm+high end torque and power.

I am still of the view that my jetting above would be closer to what it would need. This is by way of saying that yes, they got it to run OK by jetting that way, but the thing is nowhere near optimised and they are jetting to compensate and cannot optimise it because something is holding it back badly - that's all you can do in that situation. But unfortunately unless you stick rigidly to my advice I'll end up as confused you!

GC

GC

Choke 34mm

Main Jet 125

Air corrector 170-180

Idle - 45

Pump - 45 OK

And now you ran 120 mains - what choke size on F24 emulsion tube?

The cam retard (5 crank or cam degrees?) might enhance the lower end and cut the top end by reducing overlap. Hard to tell with a SOHC cam - I'd have left it alone at 106 like Cat specified - like I said - only change_one_thing_at_a_time, but now you have several new variables and a decent comparison of what worked and what didn't is er, pretty well impossible..

I wonder if it's time to go back to 106 deg. Or maybe change the header, it is too short really, I'd be specifying at least 4 " longer. I could be wrong, maybe your head flow is too low and she won't breathe higher up and maybe the cam profile is not working - but - I know one thing - over-rich jetting is nearly always a result of exhaust pressure wave interference from too-short header pipes. And tiny air correctors = way over-rich. They only influence the mixture at the top end - say 5000 plus and the fact they are so small (fuel-rich) means it is needing massive over-fuelling at the top end and struggling to get high rpm+high end torque and power.

I am still of the view that my jetting above would be closer to what it would need. This is by way of saying that yes, they got it to run OK by jetting that way, but the thing is nowhere near optimised and they are jetting to compensate and cannot optimise it because something is holding it back badly - that's all you can do in that situation. But unfortunately unless you stick rigidly to my advice I'll end up as confused you!

GC

GC

-

James Bowen

- Posts: 90

- Joined: June 23rd, 2006, 8:17 pm

- Location: Brighton, UK.

- Contact:

Guy,

Apologies if my last post confused you, I did not mean that to be the case.

To clarify....

Cam is now set at 106 deg. The Cam WAS out by 5 deg crank - advanced. ie the inlet was fully open at 101 deg. This was corrected as per original posts. I have not and will not alter it now that it is set as Catcams specify, as per previous advice.

The ONLY other thing that has been changed, is the Exhaust backbox, to the George Polley item you recommended.

The car has now been Rolling Roaded in that condition. As per last post, the fuelling issue remains the same as before we tried these measures, ie these measures don't appear to have worked, though there is some improvement in Torque.

The jetting was selected by the Rolling Road operator. I suggested 170/180 air correctors. He said they wouldn't work as the engine was too lean at the top end with these. He therefore tried to get the fuelling consistant throughout the range, and came up with the 120 mains and 115 Air correctors. Not the situation I wanted, and the conclusion is that the fundemental problem remains.

As per your most recent post, I am interested in what you feel the next avenue to try is. Primary runner length you have mentioned, and head breathing. I have not been able to try 34mm chokes, as I cannot find any at the moment, or 32's to modify. Is this difference in choke size an important enough avenue, to try before anything else?

The chap at SouthernCarbs pointed out that 1600 Xflows run either 32's or 34's for similar power/engine capacity.

Regards James

Apologies if my last post confused you, I did not mean that to be the case.

To clarify....

Cam is now set at 106 deg. The Cam WAS out by 5 deg crank - advanced. ie the inlet was fully open at 101 deg. This was corrected as per original posts. I have not and will not alter it now that it is set as Catcams specify, as per previous advice.

The ONLY other thing that has been changed, is the Exhaust backbox, to the George Polley item you recommended.

The car has now been Rolling Roaded in that condition. As per last post, the fuelling issue remains the same as before we tried these measures, ie these measures don't appear to have worked, though there is some improvement in Torque.

The jetting was selected by the Rolling Road operator. I suggested 170/180 air correctors. He said they wouldn't work as the engine was too lean at the top end with these. He therefore tried to get the fuelling consistant throughout the range, and came up with the 120 mains and 115 Air correctors. Not the situation I wanted, and the conclusion is that the fundemental problem remains.

As per your most recent post, I am interested in what you feel the next avenue to try is. Primary runner length you have mentioned, and head breathing. I have not been able to try 34mm chokes, as I cannot find any at the moment, or 32's to modify. Is this difference in choke size an important enough avenue, to try before anything else?

The chap at SouthernCarbs pointed out that 1600 Xflows run either 32's or 34's for similar power/engine capacity.

Regards James

-

Guy Croft

- Site Admin

- Posts: 5039

- Joined: June 18th, 2006, 9:31 am

- Location: Bedford, UK

- Contact:

OK, thanks for the clarification.

Let's forget chokes for now because the results even now should be better. And the peak power should definitely be higher with 34mm chokes if the cam profile is any good and the head work about right. I assume the Cat cam is a billet not a reprofiled one.

You can certainly rule out the GP silencer as a cause. I know you know that, I'm just passing this on for every reader's benefit.

Fundamentally we've got an engine here that maybe needs to be richened up and produce good top end power. I say enriched, I mean within quite confined HC and CO limits. We know it needs top end enrichment because the small air corrector has shown us, but you don't tune a carb that way. Well, you can, but if you do you're masking another problem. Either it needs more fuel (gasoline) or more air. More fuel is not as easy as it sounds because it's carried on the airstream Thus if there is a pressure wave interference problem of the head is not flowing enough air the fuelling cannot and should not be increased by simply bigger jets. All that will do is wash the oil off the bores and send the HC emissions sky-high.

Here's the deal on jets:

The main jet controls the mixture under 1/4 load + thru the whole range whereas the air corrector mainly influences the top end. To quote Weber ' by increasing the diameter of the a/c the mixture is weakened more at higher rpm than lower engine rpm' (and the converse is also true.

So, if you think the engine needs more fuel at the top end what do you do?

Well, first thing - all things being equal (ignition timing correct, fuel pump delivery OK, plugs, air filter OK etc) - is to optimise the mixture from 3000 or so up to about 4800, maybe higher. This is a critical main jet range for that motor, the first thing you look at.

What size do you give the a/c? You need experience to decide where to start. FWIW - in my exp it's unheard of to fit anything smaller than 165 in any engine I've ever done and on a little engine like that I would categorically commence with a 175 or bigger.

Similarly you commence with 'pot luck' on the main jet (you need exp to know where to start) and I'd have a 125 in there.

With a bit of luck the choice of main jet will make the mixture correct thru most of the range. If that mid range is over-rich/lean you go down/up on the main jet.

Only when that mid range is about perfect do you look at 5000 plus. Now, if it goes lean over that speed you go one size smaller (170) on the a/c and conversely if it's too rich you go to 180. You don't change the main jet.

With your motor, the main jet is not far off, but the air corrector is so small that one would ordinarily say OK let's go back to a 170 a/c and make the main jet 2 or 3 sizes bigger. But I suspect that would not have worked. The thing is really if that top end won't respond with a sensible main and a/c size it's not a jetting related problem, it is something else.

At this time my money would be on the header length or the head flows. I'm doing my best but I can't be more specific.

If you know the HC and CO figures let me see them please.

GC

Let's forget chokes for now because the results even now should be better. And the peak power should definitely be higher with 34mm chokes if the cam profile is any good and the head work about right. I assume the Cat cam is a billet not a reprofiled one.

You can certainly rule out the GP silencer as a cause. I know you know that, I'm just passing this on for every reader's benefit.

Fundamentally we've got an engine here that maybe needs to be richened up and produce good top end power. I say enriched, I mean within quite confined HC and CO limits. We know it needs top end enrichment because the small air corrector has shown us, but you don't tune a carb that way. Well, you can, but if you do you're masking another problem. Either it needs more fuel (gasoline) or more air. More fuel is not as easy as it sounds because it's carried on the airstream Thus if there is a pressure wave interference problem of the head is not flowing enough air the fuelling cannot and should not be increased by simply bigger jets. All that will do is wash the oil off the bores and send the HC emissions sky-high.

Here's the deal on jets:

The main jet controls the mixture under 1/4 load + thru the whole range whereas the air corrector mainly influences the top end. To quote Weber ' by increasing the diameter of the a/c the mixture is weakened more at higher rpm than lower engine rpm' (and the converse is also true.

So, if you think the engine needs more fuel at the top end what do you do?

Well, first thing - all things being equal (ignition timing correct, fuel pump delivery OK, plugs, air filter OK etc) - is to optimise the mixture from 3000 or so up to about 4800, maybe higher. This is a critical main jet range for that motor, the first thing you look at.

What size do you give the a/c? You need experience to decide where to start. FWIW - in my exp it's unheard of to fit anything smaller than 165 in any engine I've ever done and on a little engine like that I would categorically commence with a 175 or bigger.

Similarly you commence with 'pot luck' on the main jet (you need exp to know where to start) and I'd have a 125 in there.

With a bit of luck the choice of main jet will make the mixture correct thru most of the range. If that mid range is over-rich/lean you go down/up on the main jet.

Only when that mid range is about perfect do you look at 5000 plus. Now, if it goes lean over that speed you go one size smaller (170) on the a/c and conversely if it's too rich you go to 180. You don't change the main jet.

With your motor, the main jet is not far off, but the air corrector is so small that one would ordinarily say OK let's go back to a 170 a/c and make the main jet 2 or 3 sizes bigger. But I suspect that would not have worked. The thing is really if that top end won't respond with a sensible main and a/c size it's not a jetting related problem, it is something else.

At this time my money would be on the header length or the head flows. I'm doing my best but I can't be more specific.

If you know the HC and CO figures let me see them please.

GC

-

James Bowen

- Posts: 90

- Joined: June 23rd, 2006, 8:17 pm

- Location: Brighton, UK.

- Contact:

Guy,

Thanks for the superb, clear, concise and logical explanation. I fully appreciate that it takes a lot of time to craft a reply like that, so thank you.

OK. Assuming the above to be the case. And they certainly have to be the most likely causes. I will first change the header to longer primaries. This has to be the cheapest place to start, and the one that involves least work. On top of this, everything I've read of recent past states that Primaries need to be 30" long.

If it's the head I may have to have another crack, but this time paying closer heed to GC/workshop advice!

The only other cause of poor high rpm flow is the Inlet manifold? I do not know who made the one I have, but it is 2 piece and of poor casting quality. I did match the ports. Not much to go wrong there though I'd have thought.

I don't know if the HC and CO emissions were measured as the setting up was done with a Lamda sensor, I'll ask.

Regards, James

Thanks for the superb, clear, concise and logical explanation. I fully appreciate that it takes a lot of time to craft a reply like that, so thank you.

OK. Assuming the above to be the case. And they certainly have to be the most likely causes. I will first change the header to longer primaries. This has to be the cheapest place to start, and the one that involves least work. On top of this, everything I've read of recent past states that Primaries need to be 30" long.

If it's the head I may have to have another crack, but this time paying closer heed to GC/workshop advice!

The only other cause of poor high rpm flow is the Inlet manifold? I do not know who made the one I have, but it is 2 piece and of poor casting quality. I did match the ports. Not much to go wrong there though I'd have thought.

I don't know if the HC and CO emissions were measured as the setting up was done with a Lamda sensor, I'll ask.

Regards, James

-

Guy Croft

- Site Admin

- Posts: 5039

- Joined: June 18th, 2006, 9:31 am

- Location: Bedford, UK

- Contact:

-

sumplug

- Posts: 234

- Joined: June 25th, 2006, 10:25 am

- Location: Banned 4th Oct 07 by GC

- Contact:

James.

What type of ram pipes are you using?

looking at your two different R/R reports, i think the exhaust manifold is restricting the engine and creating pressure. Maybe this is your funny noise?

I think you need to get back to basics and get the head flowed and inlet and exhaust sorted, then look at the fueling. This engine should be making alot more power and torque.

Andy.

What type of ram pipes are you using?

looking at your two different R/R reports, i think the exhaust manifold is restricting the engine and creating pressure. Maybe this is your funny noise?

I think you need to get back to basics and get the head flowed and inlet and exhaust sorted, then look at the fueling. This engine should be making alot more power and torque.

Andy.

Who is online

Users browsing this forum: No registered users and 29 guests